May 14, 2016

Utilizing Typhoon Power to Generate Electricity with Magnus Effect-Based Vertical-Axis Wind Turbines

Keywords: Environmental Technology Renewable Energy

Initiatives are underway to accelerate the spread of wind power in Japan by developing and commercializing a typhoon power generation system capable of generating power even when winds are strong. This article about typhoon power generation is reprinted here with permission from Smart Japan, an information portal website managed by IT media and providing the latest news on conserving, storing and generating power.

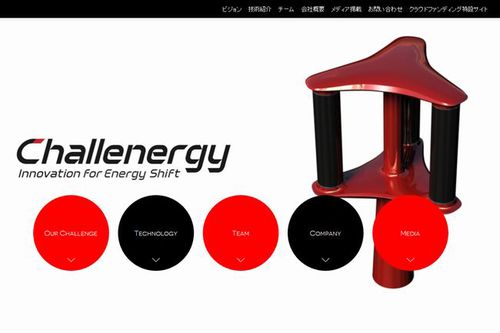

Challenergy Inc. is an R&D-oriented manufacturing startup company founded in 2014 and headquartered in the manufacturing facility called Garage Sumida, which was selected for a subsidy project of Sumida Ward, Tokyo.

Challenergy is working with Hamano Products Co., a company specializing in sheet metal processing, to commercialize a propellerless vertical axis wind turbine using the Magnus effect.

Among the world's renewable energy technologies, wind power generation is a highly efficient renewable energy technology and ranks second after hydropower generation in terms of the amount of electricity generated. However, due to Japan's over-emphasis on solar power generation, the proportion of wind power capacity in Japan remains low. There are various factors hindering the spread of wind power in Japan. One of the factors is that there are only a few places in Japan where the wind continues to blow at a constant rate.

People often think that wind power turbines run better in stronger winds, but actually it is difficult to generate electricity in strong winds such as those which blow during typhoons, because the blades may break. The Magnus effect-based vertical axis wind turbine, which is currently being developed by Challenergy, is expected to solve this problem by enabling power generation in strong winds. The company also aims to make installation possible in small spaces where turbine size previously prevented installation.

The Magnus effect-based vertical axis wind turbine is a type of wind power generator which utilizes the Magnus effect produced when a cylinder rotates in an airstream. The Magnus effect is a lifting force which acts vertically relative to the direction of travel as a result of the airstream being dragged by the rotation of a cylinder or a ball spinning in an airstream flowing at a certain speed. For example, when an airstream is flowing from left to right and a cylinder is spinning clockwise in the airstream, the Magnus force creates upward movement. The Magnus effect-based wind power turbine is a power generator which produces a lifting force and rotates by rotating a cylinder in an airstream (wind) flowing in one direction.

Magnus effect-based wind power turbines already exist, but Challenergy's turbine is different from others with its unique vertical axis design. Since it has adopted a vertical axis, the installation space doesn't have to be as large as before, and developers anticipate additional effects including improved safety and quiet operation. Moreover, the amount of power generated can be controlled by limiting the speed of cylinder rotation; therefore, the turbine can generate electricity even during a typhoon or other strong-wind environment by controlling the turbine spinning speed.

The company has developed a test model of its vertical axis wind turbine and conducted test runs indoors. In order to conduct an outdoor field test in an effort to commercialize the turbine, the company is raising money by crowd-funding.

Challenergy plans to build a test turbine in the summer of 2016, in Nanjo City, Okinawa Prefecture, and carry out the world's first demonstration test of typhoon-powered generation. This test will use a test turbine having a capacity of one kilowatt and measuring three meters in diameter and three meters in height. The field test should yield data including the amount of electricity generated using power from the typhoon, and will hopefully lead to the development of a large-scale, mass-producible model. The test preparations will require about 15 million yen (about US$125,000) to design, manufacture and assemble the test turbine as well as to prepare the site foundation. The amount collected through the crowd-funding will be used to cover part of this cost.

The funding began on January 18, 2016, and so far more than 2.5 million yen (about US$20,800) has been collected in ten days, which exceeds the target amount of two million yen (about US$16,700).

Source: Smart Japan (in Japanese)

Related JFS Articles

Related

"JFS Newsletter"

Related

"Popular Articles"

- New Nano-Bubble Technology May Help Dissolve Sludge and Improve Water Quality

- Japanese Firm Begins Development of Tidal Power Generation System

- Small Hydropower Generation System Developed for Use in Seawater, Weight Cut by Half

- Constructed Wetland Facility Established by Japanese University Purifies Livestock Farming Drainage

- Toyota CRDL Succeeds in World's First Artificial Photosynthesis Using only Water and CO2